What Is UV Varnish?

Applied using a screen-printing process, selective UV varnish (Spot UV) highlights only the desired elements on a press sheet, such as a logo or design. We offer several types of varnish to enable you to achieve a wide range of finishes while remaining as original as possible.

The minimum size for selective varnish is 12 x 18 and the maximum size is 28 x 40. The minimum thickness is 200m (5 pts) and the maximum is 24pts.

Is It Possible to Perform a Full UV?

We also have a UV varnish press for full-surface applications (glue flaps can be detached) of press sheets. Minimum size is 17½ x 23 and maximum size is 28x40.

Minimum thickness is 160m and maximum is 24 points. Although it is possible to apply a screen-printed varnish over the entire surface, the quality will be inferior because the quantity of varnish used is much greater than on our press.

What Criteria Must Be Met?

It is essential to leave a 5/8" gap with the gripper. It's also important to note that sheets should never be cut according to the side guides. We need these guides for positional accuracy.

It's advisable not to apply primer or water base to the sheets to ensure varnish adhesion, but we also understand that these days, printing without protection is playing with fire.

How about an eco-friendly lamination approved for food contact?

Selection of Varnishes

Ultraviolet Gloss Varnish:

MORE INFORMATION

MORE INFORMATIONThis type of varnish is a basic gloss varnish. Ultra-glossy, it can be used to highlight details or for full-surface coating. It is not approved for food use, and cannot be glued or stamped. It is always advisable to apply it to a matte surface to highlight it.

Ultraviolet Semi-Emboss Gloss Varnish:

MORE INFORMATION

MORE INFORMATIONThis varnish is mainly used to give thickness to certain elements. It is not recommended for large masses. The thickness of this type of product is around 50 microns. Do not cut, bend or score in this type of varnish, or there is a risk of cracking.

Ultraviolet Matte Varnish:

MORE INFORMATIONThis varnish gives a matte effect. It can be applied to small details or full surfaces. Note that it is not scratch-resistant, so it is not recommended for dark colors. Note that it's always best to apply it to a glossy surface to give a contrasting effect.

Ultraviolet Matte Rough Varnish:

This varnish gives a rough effect to certain elements on a print. We do not recommend full-surface application, as it may crack or warp the paper.

Ultraviolet Sanded Varnish:

To create the sandblasted effect, we add particles to the varnish. It can therefore be offered in both gloss and matte finishes. As with UV Matte Rough Varnish, this product is not recommended for large surfaces.

Ultraviolet Glitters Varnish:

MORE INFORMATION

MORE INFORMATIONLike UV Sanded Varnish, we add particles to the varnish. It is available in gold, silver, multicolor, red, green, and blue. However, a certain quantity may be required for certain colors. It's important to remember that we can't guarantee 100% consistency, since these are flakes that pass through the silk mesh on the machine, and our control is limited. This varnish must not be cut, folded or scored.

Ultraviolet Pearl Varnish:

Like the Sanded and Glitter varnishes, we add particles that give the varnish a pearlescent effect. Once again, we do not recommend large surfaces, cutting, folding or scoring in this type of application.

Ultraviolet Thermochromic Varnish:

MORE INFORMATIONThis varnish gives an incomparable effect to your prints. In fact, this product changes color according to temperature. For example, a version we stock is translucent when exposed to heat, but turns opaque black when cooled.

Ultraviolet Glow-in-the-Dark Varnish:

MORE INFORMATIONIf you want to give a glow-in-the-dark effect, this is the varnish for you. We add a particle to the varnish that absorbs light and reflects it when it's dark. We always suggest applying it to light colors, but it can also be applied to dark colors, but the effect is less noticeable. Like most special varnishes, we advise against applying it to large surfaces.

Ultraviolet Chalkboard Varnish:

To give your printed matter a chalkboard effect, you need to use this varnish. Once applied to the board, it can be written on with chalk in the same way as a chalkboard. It can be applied in large areas, but you must not cut, fold or score in this varnish.

Scented Varnish:

This varnish adds fragrance to your print. We commonly produce banana, strawberry and watermelon scents, but there's a ton of scents out there. For best results, do not apply water-based press varnish. Our scented varnish requires some penetration into the cardboard, as it's a scratch-&-sniff type of varnish. Results are even better with porous cardboard.

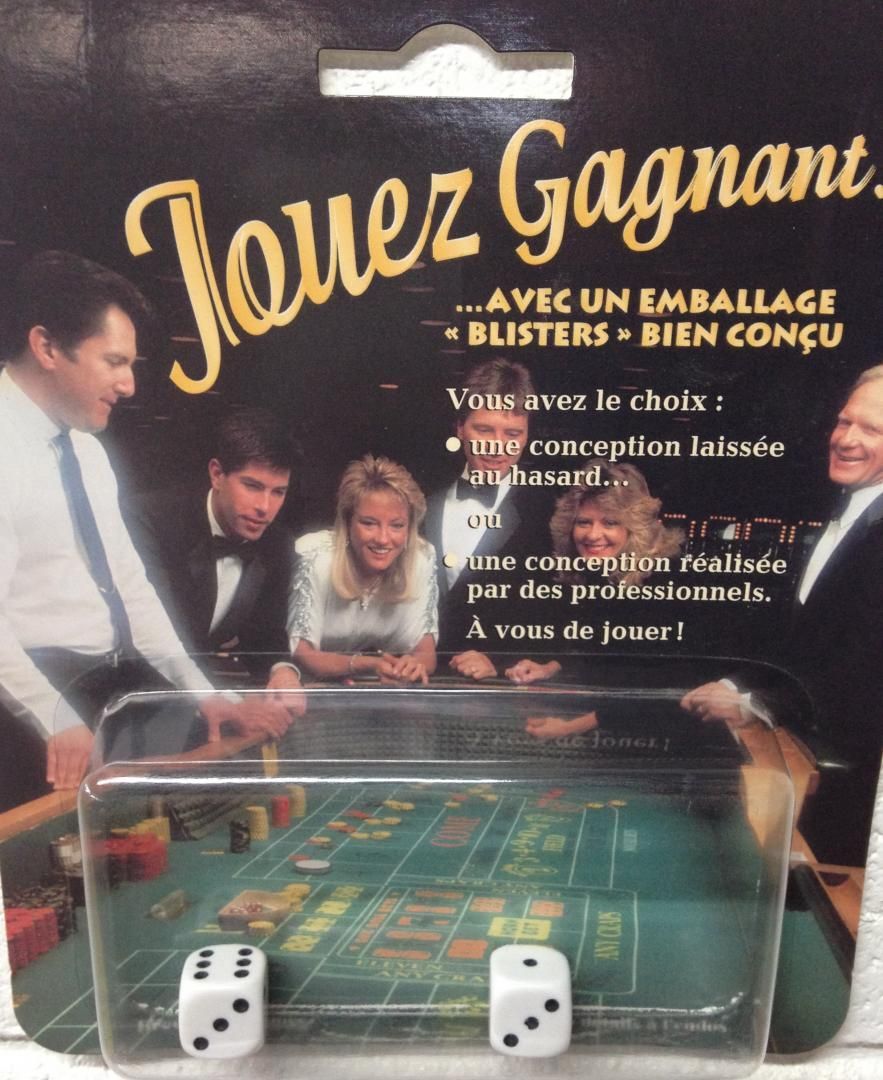

Blister Varnish:

This varnish is not an ultraviolet varnish. It's a coating that dries under heat. It can be used to seal a PET cap. Please note that we offer the varnish application service, but not the sealing service. It should also be noted that this varnish can only be applied to coated blister boards.